Due to the nature of the power chuck’s wedge design, the large contact areas generate a lot of friction. Combine this with the high axial loads and you get a very large variation in performance between a chuck that is well lubricated and one that is not, this can equate to as much as 30% loss in grip force!

Take into account centrifugal grip loss and if running in the higher RPM range of the chuck it would be possible to find the chuck unable to hold onto the component.

Having a consistently greased chuck will give you a consistent coefficient of friction between the wedge plunger and base jaws and produce more consistent safer working condition.

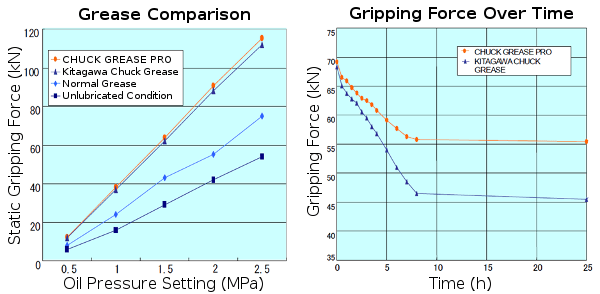

Kitagawa have developed their own special variety called Kitagawa “Chuck Grease Pro” this is not an off the shelf product, Kitagawa spent 3 years testing and developing the optimum grease for use with Kitagawa chucks.

Chuck Grease Pro out performs Kitagawa’s previous grease and standard LM grease significantly and the drop in performance is also reduced by as much as 14%.

It’s a very common question and the answer is simple. Once per 8 hour shift a small quantity of grease should be pumped into each grease nipple and every 6 months or so the chuck should be removed from the machine and disassembled.

All of the grease galleries should be cleaned, as they have a habit of becoming blocked if chucks are not regularly greased. If starting a new regime of greasing it is worth completely disassembling and cleaning first off, to make sure the grease is getting to all the parts it needs to.

If you have any more questions about greasing your chucks, you can arrange a FREE visit from one of our technical representatives by contacting us on 01725 512517 or enquiries@1mta.com. We look forward to hearing from you.

Kitagawa Chuck Grease Pro comes in a couple of different sizes, the 400g cartridge for use with our Lever Action Grease Gun, and the 1KG tin for use with our Pump Action Grease Gun.