For when your workholding requirements can’t be met by standard clamping options, 1st Machine Tool Accessories have an in-house design team who are ready, willing, and able to provide a solution.

1st MTA are able to design custom solutions for specific work pieces that otherwise wouldn’t be able to be held by standard chucking systems. Presented here is a typical procedure for enquiries that we recieve.

Going from a drawing and raw workpiece that we’re given, we identify the customer’s requirements and select a suitable workholding solution. We create a CAD drawing of the workpiece that can be much more easily manipulated.

Using the CAD drawing, a complete concept solution including the chuck and any modifications required is created. In this particular example, extra weights were added to ensure concentricity of the chuck. Once the final design is approved, it is manufactured and tested to ensure complete viability.

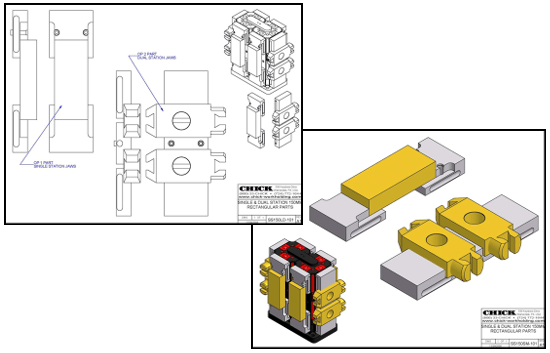

For holding unique parts on a machining centre, 1st MTA can design custom jaws and faceplates for the Chick System 5 range of products. Whether it be large components that are tricky to grip, or maximising the number of workpieces in the machine per cycle, the versatility of the Chick range allow possibilities for both.

Using Chick Jaws as a basis, we can create a drawing based on the specification of your workpieces. This example concept performs two operations in a single machining cycle.

The jaw concept can be used on a Chick Multi-Lok, allowing both OP1 and OP2 to be completed during a single machining cycle, with OP1 held in single station jaws, and OP2 held in a different orientation using dual station jaws.

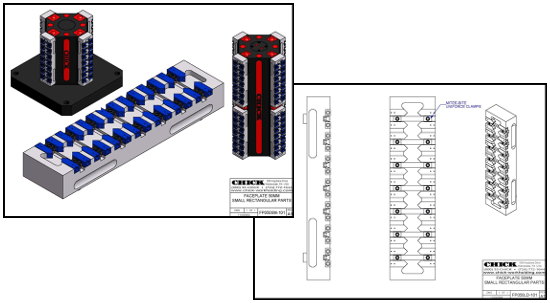

For much smaller workpieces, a Chick faceplate can be used. Fixtures can be added to hold multiple parts on each faceplate, and they can be designed so that the maximum number of parts are clamped at a single time. The faceplates can also function as a mini pallet changer, allowing one faceplate to be in the machine, whilst the other is outside having parts removed to be setup for the next machining cycle.

The faceplate can be used on either a standard Multi-Lok or a double-high Multi-Lok, greatly increasing the number of parts in the machine at once. Different size and shapes of Multi-Lok are available to get the most from your machining envelope.

If you are having any issues with your current workholding, or anticipate trouble with any upcoming projects, please contact us on 01725 512517 or enquiries@1mta.com to speak to one of our in-house technical team. They may be able to advise you over the phone, or offer a FREE on-site visit from one of our technical representatives. We look forward to hearing from you.