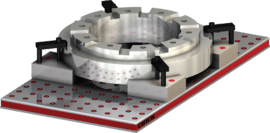

Chick Foundation Plates provide critical repeatability and consistency to clamping processes, and are custom-made to fit a CNC machining centre envelope with sizing from as small as required, to the size of the entire machine bed. A labelled 50mm grid pattern allows easy building, cataloguing, and accurate location of workholding setups, with easy maintenance thanks to the Foundation Plate’s clean, closed surface.

The full range of Chick Workholding products, along with any and all other existing fixtures and workholding, can be quickly and easily located onto the Foundation Plate, allowing different setups to be utilised on the same machine whilst drastically reducing the machine downtime.

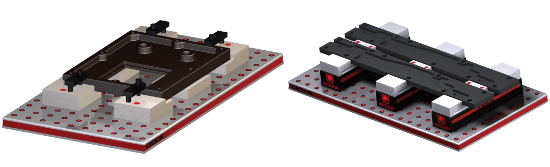

For designing component modular fixtures for extremely large parts the Foundation Plates allow you to use the entirety of your machine bed, ensuring there is no wasted space on your machine.

Chick Foundation Plates are precision ground cast iron to 35mm thick, with the length and width tailored to the machine’s work envelope. All Chick Foundations incorporate an alpha-numeric labelling system to simplify building and cataloguing fixtures. Each hole within the 50mm grid pattern has a 12mm bushing for accurate location and an M12 thread for bolt down. These holes are sealed with patented chip plugs preventing the build up of chips. The machine interface mounting holes are customised for each machining centre, and the hardware necessary to mount the Foundation to your table is included.

For designing component modular fixtures on your Foundation Plate, Chick manufacture Foundation Blox which are blank, high strength aluminium blocks that are machined to your requirements. For unparalleled repeatability use Chick Accurate Bolts. These M12 bolts have a ground shoulder that provides precision repeatability when using Foundation Blox or any other modular fixturing components.

If you would like more information on Chick Foundation Plates, contact us on 01725 512517 or enquiries@1mta.com to speak to one of our technical engineers or arrange a FREE on-site visit from one of our technical representatives. We look forward to hearing from you.

| Book a FREE onsite visit |