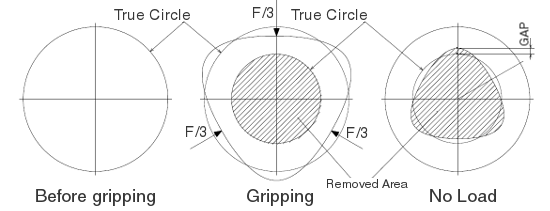

In the production of thin walled components many people struggle with deformity; resulting in products being out of round or machining not being within specified tolerances.

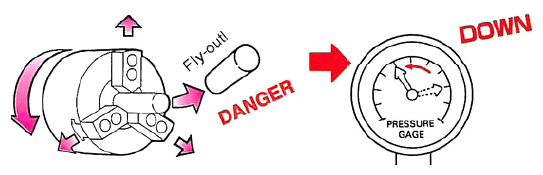

Many workshops will attempt to get around this by reducing gripping forces to such low levels that may result in parts flying out of the chuck.

At 1st Machine Tool Accessories we offer many different methods of holding thin walled components, one of these is the Abbott Pie Jaw.

Available to suit almost any chuck these can be a great way of making sure your components hold their shape. By increasing the gripping from just 3 concentrated points to a 360° contact, the force is evenly distributed around the whole circle allowing a greater degree of accuracy when machining.

Using pie jaws for both internal and external gripping will result in being able to use higher gripping pressure, meaning you can safely run your thin walled components at higher speeds without the worry of fly-out. The pie jaws are not limited to just manufacturing circular parts, they can also be very useful for getting a fuller grip on many strange profiles.

Coming in a variety of heights and available in both Steel and Aluminium, pie jaws are the ideal way to ensure you are not going round in circles with manufacturing thin walled components. Extruded from aerospace aluminium alloys, the aluminium Abbott Pie Jaws are a fraction of the weight of standard steel pie jaws but also offer strength and durability.

1st Machine Tool Accessories hold a large variety of these jaws in stock. To see what pie jaws are available for your chuck, have a look at our new Chuck Jaw Finder where you can find all jaw options from aluminium soft jaws to hardened billet gripper jaws.

For holding larger thing-walled components the Abbott Master Plate and Segment system is a great choice. The system consists of an aluminium master plate, similar to a thin pie jaw, which is pre-drilled and keyed to accommodate Abbott’s standard, off-the-shelf segment rings.

If you would like to discuss pie jaws any further, you can contact us on 01725 512517 or enquiries@1mta.com to speak to one of our technical engineers, or arrange a FREE visit from one of our technical representatives. We look forward to hearing from you.