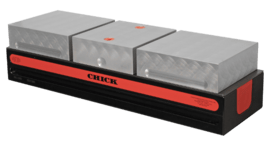

Chick Workholding was designed with flexibility in mind. Maximize your productivity and drastically reduce your repeat setup time, thereby unleashing milling profitability. The Chick Qwik-Lok is supplied with dual station jaws as standard, but is complemented by the versatility of the different machinable jaws and faceplates available. The QwikChange rapid jaw-change system allows the capabilities […]

Read more

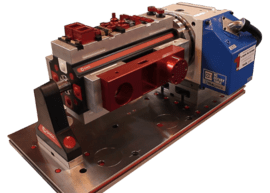

The Chick Indexer SubSystem combines the productivity and versatility of the Chick Multi-Lok with a 4th axis rotary table, thereby converting a vertical machining centre to work like a horizontal. Providing increased efficiency throughput on the vertical machining centre by turning it into either a four sided eight-station system, a six sided twelve-station system, or […]

Read more

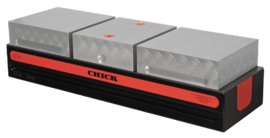

The Chick Workholding System 5 Multi-Loks are the perfect solution for horizontal CNC machines. They can take full advantage of your machine by providing the accessibility of three part sides, thus decreasing cycle times and increasing the accuracy of your parts. Available in different shapes and sizes, the Multi-Loks are flexible enough to suit any […]

Read more

System 5 from Chick Workholding was created to eliminate downtime in all its forms because if a machine is not cutting, it’s not making money. The Qwik-Lok has the ability to reduce set-up and changeover times, plus maximise the number of parts in a single machining cycle, keeping the machines cutting and making money. The […]

Read more

The Chick One-Lok vices for CNC machine tools represent an evolution in workholding technology in terms of speed, productivity, flexibility, and accuracy. The Chick One-Lok has been developed from scratch to meet the speed, precision, and flexibility demanded by modern CNC machining operations. The patented “QwikSlide” allows the moveable jaw to be unlocked to slide […]

Read more

In the production of thin walled components many people struggle with deformity; resulting in products being out of round or machining not being within specified tolerances. Many workshops will attempt to get around this by reducing gripping forces to such low levels that may result in parts flying out of the chuck. At 1st Machine […]

Read more

Darex offers the world’s bestselling state-of-the-art sharpening tools for your business. Extend the life of your cutting tools with the full range of commercial drill sharpening products and parts. The Darex XT-3000 is an expandable tool sharpener that grows as your shop’s needs grow. When you want the right point sharpened quickly and simply, the […]

Read more

Batch sizes on the increase and you want to fit more parts in your vertical miller? Already invested in vertical milling machines but your needs have changed? Wish you had a horizontal miller but don’t have the space? Introducing the Indexer Subsystem If you want to improve the productivity of your vertical milling machine, the […]

Read more

If a component has at least one flat side, then securing it for a further machining operation, on a mill for example, is a lot easier than if the part is perfectly round. For the latter type of workpiece, clamping can be problematic, as there is a tendency for the component to slip and turn […]

Read more

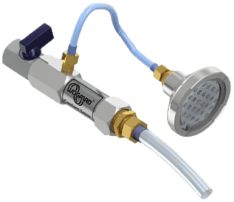

The Wogaard Coolant Saver collects the cutting-fluid that is normally wasted through the machine tool’s automatic chip conveyor. The cutting fluid is reclaimed from the chip-container and returned to the machine tool’s main tank for re-use. Cut the costs of cutting fluid by up to 50% A greener business does not neccessarily mean an increase […]

Read more