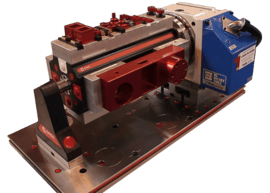

In need of a horizontal miller but haven’t got the space? The Chick Indexer Sub System could be the answer to your prayers. The Chick ISS is a workholding system which mounts to a rotary table and provides four or six sides on which to mount your workpieces. As such, it combines the productivity and versatility of the Chick Multi-Lok with a 4th axis rotary table, allowing a vertical machining centre to work like a horizontal.

The ISS has similarities to a tombstone but this innovative solution is supported on both ends, allowing the milling spindle to approach the workpiece in the same orientation as in a horizontal miller.

– The ISS can be supplied as a package with a 4th axis rotary table, or alternatively, they can be fitted to your existing set up.

– As with the rest of the Chick System 5 range, the Chick ISS also uses the same trusted quick change system.

– Additionally, the built-in zero point system makes it easy to replace the jaw with machinable faceplates for both large quantities of smaller components and small quantities of larger components.

– Another added benefit is the reduction in your setup times and providing an easy solution for complex component clamping without the need for expensive fixtures.

The Chick ISS system allows for the completion of multiple machining operations in a single machining cycle. This will mean much longer periods of unattended running or even lights out running, lowering your labour costs significantly.

If you would like to see a Chick Indexer Subsystem in action, please watch the following video: