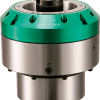

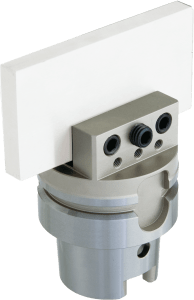

AHK Hydraulic Zero Point

Swift Klamp Base Units

Key Features

- Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder.

- Low-pressure hydraulic (3.5MPa)

- Air Detecting poor work holder seating

- Air Blow Prevents the intake of cutting chips

Description

Swift Klamp is a work-piece clamping system that maximizes the performance of your 5-axis machining center. Swift Klamp uses the time proven HSK-A type tool holding system for mounting workpieces. Each Swift Klamp base unit will accept a range of workholders uncluding dovetail, flange, side clamp, collet and others and provides excellent workpiece accessibility with reduced interference. These AHK series base units are hydraulically actuated using a built in double action cylinder and use compressed air to prevent the intake of debris as well as for seating confirmation. They require only 3.5Mpa of hydraulic pressure to operate and their simplicity makes automation easy. Klamp HSK heads can be mounted directly to 5-axis machine tables with a mounting plate that includes the hydraulic and pneumatic connections.

Estimated delivery: 7-10 Working Days (subject to availability)